Tefablock

Versatile family of thermoplastic elastomers (TPE). Applies to most of the environments and plastic converting processes.

TECHNOLOGIES

EFABLOC™ incorporates several technologies including TPE-S, TPO and TPE-E. Among the large scale of possible properties, some of them are also boosted in process by reactor or dynamic cross-linking. The accurate combination of features leads to tightly satisfy application specifications even the most demanding ones.

STANDARD TO TAILOR MADE SOLUTIONS

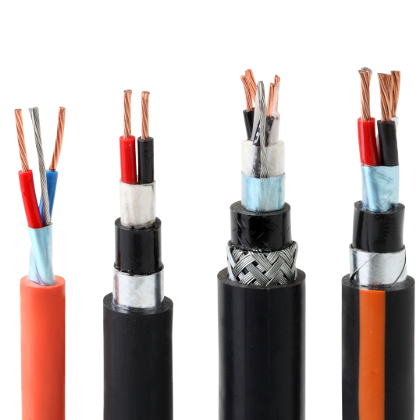

TEFABLOC™ is available for

- Standard for injection and extrusion

- Homologated from official bodies as well as with OEMs approvals

- Customized to specified properties

Flexible

- Ultra soft to semi rigid

- Elastic memory

- Multi-material chemical compatibility

Resistant

- Superior UV resistance

- Mechanical properties

- Chemical inertness

Attractive

- Matte to glossy surface appearance

- Easy coloring

- OEM pre-pigmentation

Safety

- Food contact

- Flame retardant

PROCESSES

Whether it is for single or multi-material parts, TEFABLOC™ is easy to process either in injection or extrusion. Rheology may also be adapted for hollow parts manufacturing (extrusion-blow, injection-blow) as well as blow-extrusion and recently developed 3D printing-FDM process.

Main Properties

Softness

Compression Set / Elastic Recovery

UV / Weathering Conditions

Elevated Service Temperature

Adhesion on Engineering Polymer