Adhesion to EPDM

Manufacturing of flexible junction between cross-linked EPDM parts as well as TPE or PP ones

TECHNOLOGY

To realize a flexible and continuing junction between 2 parts made of EPDM rubber usually requires to make it by the injection of EPDM in between. However, this process is quite complicate and moreover it is low in productivity

TEFABLOC™ TESL362 is a TPE offering a strong adhesion to cross-linked EPDM, and because it is a thermoplastic elastomer it doesn’t require any post curing nor specific surface treatment.

TEFABLOC™ TESL362 may also be used to associate both EPDM rubber and other TPE parts

BENEFITS - PROPERTIES

- Strong chemical adhesion to EPDM and other TPEs, as well as PP

- Do not require surface treatment nor primary

- Excellent UV resistance

- COF may be adjusted for low coefficient of friction

- Softness 75 Shore A hardness

- High productivity

POSSIBLE MATERIAL ASSOCIATIONS

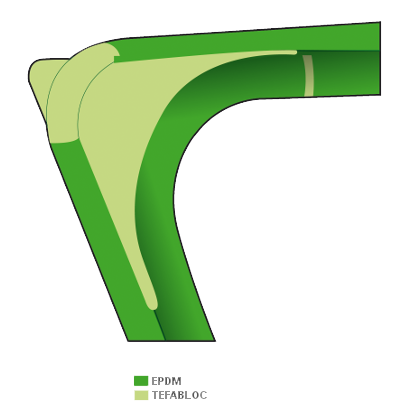

- EPDM / TEFABLOC™ / EPDM

- EPDM / TEFABLOC™ / TPE

- EPDM / TEFABLOC™ / PP

APPLICATIONS

Flexible junctions between EPDM parts by using thermoplastic injection process and avoiding necessary EPDM post curing.

One of the typical application is the corner molding of EPDM glass run channels for automotive sliding glasses.